E-mail: info@plywoodworking.com Phone: +8615854986399

E-mail: info@plywoodworking.com Phone: +8615854986399

Specification

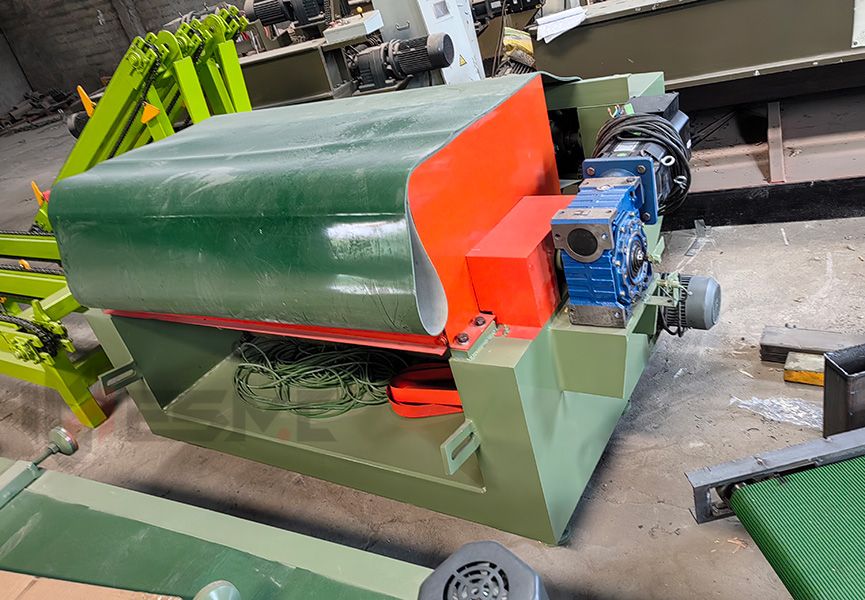

Model: ESM-1400HD2

Veneer thickness: 0.3-4 mm

Log length: 1300 mm

Processing diameter: 40-500 mm

Peeling speed: 30-100 m/min

INTRODUCTION

Producing Fruit Packaging Boxes Using Veneer Peeling

Produce fruit packaging boxes by peeling veneer method from logs using specialized veneer peeling machines. The veneer is then processed into lightweight, durable fruit boxes.

Steps:

Peeling: Logs are peeled into thin, even veneer using a veneer peeling machine. This veneer is light and strong, perfect for fruit packaging.

Assembly: The veneer is cut to size and assembled into boxes.

Finished Product: The boxes are lightweight, breathable, and eco-friendly, ideal for packing and transporting fresh fruit.

This method produces high-quality fruit boxes with smooth veneer and precise thickness.

Peeling Veneer and Cutting into Narrow Strips with a Rolling Veneer Slicer

After peeling veneer, we use a rolling veneer slicer to cut the veneer into narrow strips. The veneer is smooth and uniform, and the slicing width has minimal error.

Key Points:

Veneer Peeling: Logs are peeled into even, smooth veneer, ensuring good strength and a quality surface.

Rotary cutting machine: The veneer is cut into narrow strips with precise control, ensuring minimal width error.

This process produces high-quality, smooth veneer with accurate dimensions, making it ideal for fruit packaging boxes and other similar products.

TECHNICAL PARAMETERS

| MODEL:ESM-140ZP | UNIT | PARAMETERS |

| Log diameter | mm | 30-500 |

| Log length | mm | 1300 |

| Veneer thickness | mm | 1-3 |

| Peeling speed | m/min | 30-100 |

| Knife carriage motor power | kw | 11, servo motor |

| Double roll power | kw | 7.5, 2 units |

| Single roll power | kw | 7.5, 2 units |

| Rotary clipper machine | kw | 4, servo motor |

| Weight | kg | 6000 |

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

woodmachine@hotmail.com

Address:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.