E-mail: info@plywoodworking.com Phone: +8615854986399

E-mail: info@plywoodworking.com Phone: +8615854986399

Specification

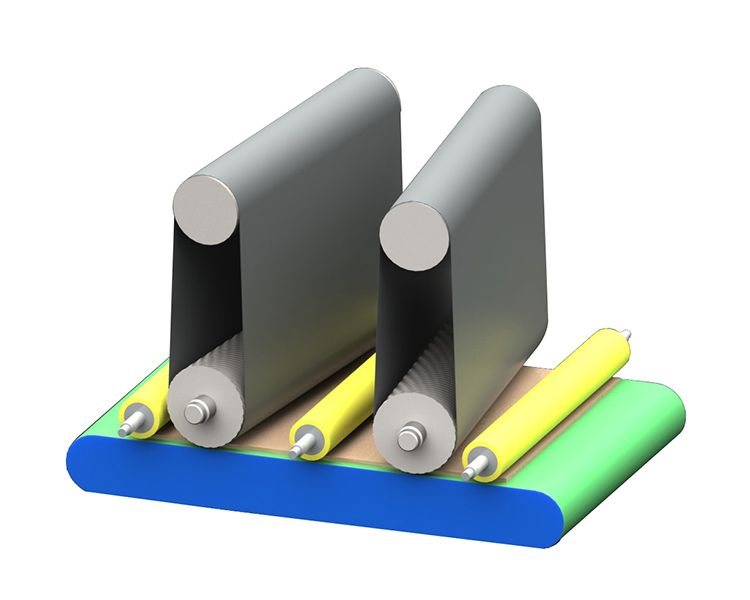

MODEL: ES-1213R-R

Sanding width: 40-1300 mm

Sanding thickness: 8-80 mm

Abrasive belt speed: 25m/s

Sanding belt size: 1360*2620 mm

Main sanding motor: 55kw,1 45kw ,1

Feed motor power: 7.5kw

Lifting motor: 0.75 kw

Dust extraction amount: 7800 m³/s

Roller diameter: 300 mm, 320 mm

Our wide belt sanding machine, designed to cater to various needs in the woodworking industry. This multi function sanding machine can be used in the wood working processing: precise and efficient sanding, thickness calibration, polishing works, and finishing for a range of materials including different plywood, block board, MDF, and second time processed and painting boards. Getting the fine surface result.

key features:

1.Thickened steel plate, stable structural framework. The framework undergoes processing by high-precision machining centers, ensuring high precision and stability of the sanding machine.

2.The processing workshop boasts over 20 years of mechanical production experience, with continuous innovation and improvement in technology. Our expertise in sanding production for panel materials has been continually optimized to achieve the best results.

3.Customization Settings

Adjust he sanding process to your specific requirements with boards panel sanding needs settings. From adjusting the sanding speed to selecting the appropriate sanding belt grit size, you have full control over the sanding parameters based on your own special plywood,block board technique, enabling you to achieve optimal results for each material.

4. Enhanced Efficiency

Designed for efficiency, our wide belt sanding machine optimizes workflow and productivity. With its high-speed sanding capabilities and automated features, you can streamline your production process and meet tight deadlines without compromising on quality.

5. Superior Surface Finish

Whether you're aiming for a smooth, matte surface or a glossy polish, our machine delivers consistent results, enhancing the better appeal of your finished products.

6. Durability and Reliability

Built to withstand rigorous use in industrial settings, our wide belt sanding machine is constructed from high-quality materials,electric parts and components. Ensures long-term durability and reliable performance, minimizing downtime and maintenance costs.

7. User-Friendly Interface

Touch screen interface and combined convenient physical control button, our machine is easy to operate and command operating .The user-friendly controls simplify the sanding process, allowing operators to focus on achieving optimal results with minimal effort.

8. Safety Features

Safety is paramount in any woodworking environment, which is why our wide belt sanding machine is equipped with comprehensive safety features. From emergency stop buttons to protective guards, we prioritize the well-being of operators while ensuring efficient operation.

9. Application Versatility

Whether you're a plywood or block board factory ,furniture manufacturer, cabinet maker, or woodworking enterprise, our wide belt sanding machine focus on a wide range of applications. From small-scale projects to large-scale production, it's the perfect solution for achieving professional-quality finishes.

10. Commitment to Quality

Strict testing and inspection to uphold the highest standards. We stand behind our product, offering unparalleled support and service to meet your needs.

Experience the difference our wide belt sanding machine can make in your woodworking endeavors. Contact us today to learn more and discover more details.

After Sale :

Pre-sale services:

1) Free consult to help you choose suitable veneer making or plywoodworking machine.

2) Base on your production improvement or equipment upgrading needs, make full set plywood,veneer production solutions. and offer the machine drawings.

3) Offer detail machine technical parameters and quotations, after confirm each other, sign the PO or invoice.

4) Invite customers to visit workshops and test plywood machine working.

Services during the sales:

1) Updating the machinery manufacturing process.

2) Strict inspection of machine quality during each manufacture and assemble process and detail tesing before delivery.

3) Free training the machine operating and using, make the user manual help customer comand the skills.

4) Confirm the custom clearance documents and prepare delivery.

After sale services:

1) 7/24 hours engineer ready to service to solve problems.

2) Full life spare parts and online machine debugging supporting.

3) Professional engineers installing and trainning service.

4) overseas service of machine upgrading and maintance.

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

woodmachine@hotmail.com

Address:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.