E-mail: info@plywoodworking.com Phone: +8615854986399

E-mail: info@plywoodworking.com Phone: +8615854986399

Specification

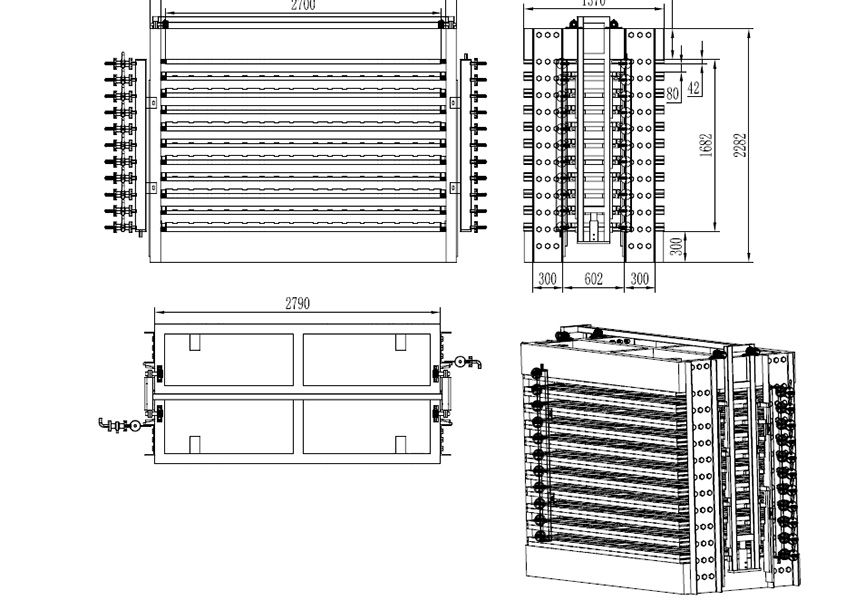

Model: HG-4x8.20S

Boards feed direction: vertical

Hot platen size: 2600x1400x40mm

Layer quantity: 20 layers

Work method: 10 opens and 10 close

Oil cylinder: 120mm*2-4Pcs

Oil cylinder stoke: 1200 mm

Work Pressure: 60T

Capacity: 0.7-1 CBM

The layers are half close and half open design.for example 10 close 10 open. Every layer can put in several veneers one time. Easy operation. Practical using and low costs. Quality oil cylinder and structure frame, easy maintain. With lower investment than the hot platen type. Suits several units start the veneer drying processing at beginning.

Seamless Pipe combine as the heating platen or extraly add one steel platen on the surface and back of the platens. Good for moisture exhaust. (8close,8 open,10 close, 10 open)

This kind veneer drying machine with lower investment, small space need.More convenient for common veneer production factory. The heating is available by different kinds boiler supplying.

ESMC focus on the plywood and veneer working, can supply you various kinds veneer drying machine according to your production needs such as the multi layers veneer press dryer machine, roller type drying line, mesh type veneer drying line or combined veneer drying line.For those equipment, feel free to contact and communicate.

Main Advantages:

This hollow platen type dryer also called the square pipes type veneer dryer machine

1.Final core veneer moisture conten can arrive 15-20%.

2.Core veneer (moisture within 20%-15%) drying and flatting.

3.Take with standard steel plate and square pipe keeping good heating drying performance.

4.Greatly improve the veneer flat and quallity. make it better the plywood production.

5.Compare its investment, the capacity is good:16-20 layer hollow platen press dryer can be 0.7-1m3 per hour.

After Sale :

Pre-sale services:

1) Free consult to help you choose suitable veneer making or plywoodworking machine.

2) Base on your production improvement or equipment upgrading needs, make full set plywood,veneer production solutions. and offer the machine drawings.

3) Offer detail machine technical parameters and quotations, after confirm each other, sign the PO or invoice.

4) Invite customers to visit workshops and test plywood machine working.

Services during the sales:

1) Updating the machinery manufacturing process.

2) Strict inspection of machine quality during each manufacture and assemble process and detail tesing before delivery.

3) Free training the machine operating and using, make the user manual help customer comand the skills.

4) Confirm the custom clearance documents and prepare delivery.

After sale services:

1) 7/24 hours engineer ready to service to solve problems.

2) Full life spare parts and online machine debugging supporting.

3) Professional engineers installing and trainning service.

4) overseas service of machine upgrading and maintance.

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

woodmachine@hotmail.com

Address:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.