E-mail: info@plywoodworking.com Phone: +8615854986399

E-mail: info@plywoodworking.com Phone: +8615854986399

Specification

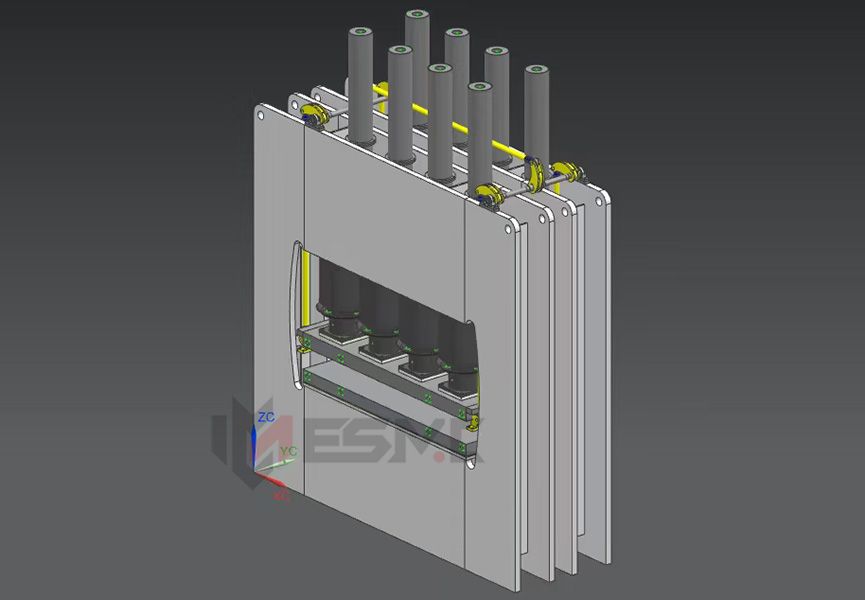

MODEL: ESM-SC4X8

Pressure: 1200-2400 T

Hot Platen Size: 1400*2600 mm

Hot Platen Thickness: 140/100-160/120

Main Frame Steel Plate Thickness: 50-90 mm

Oil Cylinder Size: Ø320-400 ,8 units

Main Motor Power: 23 kw

Strong and strengthen quality frame structure full welding.Keep working quality. High pressure pressing quality.Quickly closing speed, safe working confirm. Making the boards with pretty good rate of finished products.

Main frame structure inside stress angle take with high standard steel plate processed on CNC machining center, smooth surface keep frame with enough strength for big pressure working and long term production.

Insulating pads, high temperature and wear resisting seal used on the important oil cylinder, confirm sooth working and longer service lift.

Hydraulic system using cooling device to prevent high temperature damage.

Synchronizing system keep hot press lifting and falling with better parallel, improve the lamination quality and finished products rate.

Also suits the veneer lamination processing on particle board, MDF board. And melamine impregnated paper or high density laminated flooring wear resisting paper. The size from 4*8 ft ,6*9ft to maximum board size 6*12 ft. And the pressure from 1200T,1600T to 2400T and 3200T.

We can offer you full automatic short cycle lamination line to your production include auto board feeding and unloading, auto laminated paper edging and auto board stacking.

| Model | 1200T | 1600T | 2000T | 2400T |

| Panel board size | 1220*2400 mm | 1220*2400 mm | 1220*2400 mm | 1220*2440 mm |

| Rated working pressure | 1200 T | 1600 T | 2000 T | 2400 T |

| Hot platen size | 1400*2600 mm | 1400*2600 mm | 1400*2600 mm | 1400*2600 mm |

| Hot platen thickness | 140/100 mm | 140/120 mm | 160/120 mm | 160/120 mm |

| Oil cylinder sizw | Ø 320 ,6 | Ø 320, 8 | Ø 360, 8 | Ø 400, 8 |

| Main frame steel plate thickness | 50 mm | 60 mm | 70 mm | 90 mm |

| Main motor power | 23 | 23 | 23 | 23 |

Please feel free to contact for the hot press, cold press, laminating hot press machine. We will try best make the good and stable veneer plywoodworking machine to you. And offer the full term after sale service. ESMC appreciate your support and trust.

After Sale :

Pre-sale services:

1) Free consult to help you choose suitable veneer making or plywoodworking machine.

2) Base on your production improvement or equipment upgrading needs, make full set plywood,veneer production solutions. and offer the machine drawings.

3) Offer detail machine technical parameters and quotations, after confirm each other, sign the PO or invoice.

4) Invite customers to visit workshops and test plywood machine working.

Services during the sales:

1) Updating the machinery manufacturing process.

2) Strict inspection of machine quality during each manufacture and assemble process and detail tesing before delivery.

3) Free training the machine operating and using, make the user manual help customer comand the skills.

4) Confirm the custom clearance documents and prepare delivery.

After sale services:

1) 7/24 hours engineer ready to service to solve problems.

2) Full life spare parts and online machine debugging supporting.

3) Professional engineers installing and trainning service.

4) overseas service of machine upgrading and maintance.

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

woodmachine@hotmail.com

Address:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.