E-mail: info@plywoodworking.com Phone: +8615854986399

E-mail: info@plywoodworking.com Phone: +8615854986399

Specification

Model: ESM-4SAW

Cutting size: 1220*2400 mm

Ajusting size range: 3*6' to 4*8'

Sawing thickness: 3-60mm

Saw blade motor: 9 kw *4 units

Transfer motor: 2.3kw*2

Capacity: 2000-3000 pcs/day

Install size: 6500*5000*1200mm

Weight: 5800 kg

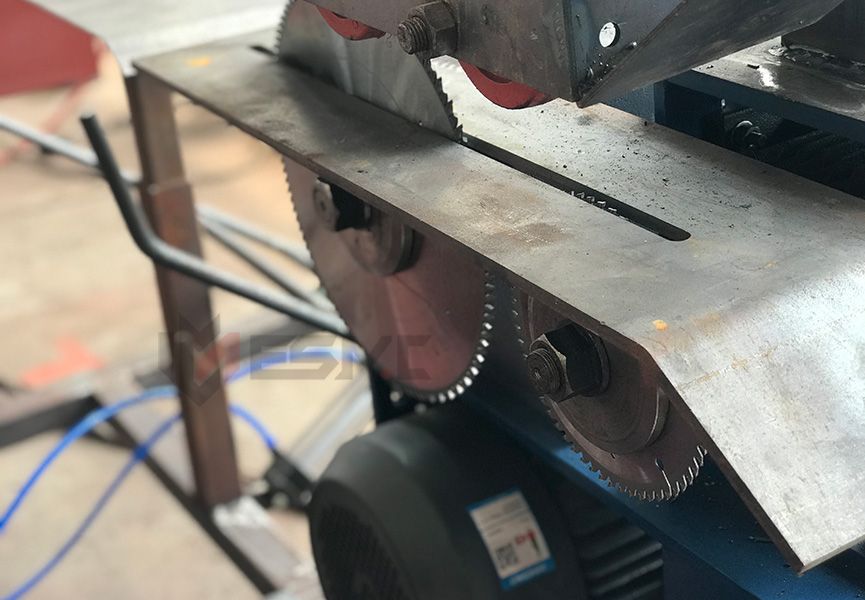

Auto 4 sides Sawing machine introductions:

This model plywood trimming saw works on the plywood rough edge cutting.4 sides edging. Manual feed boards and auto cutting, stacking or full automatic feeding the boards, sawing and and stacking both available.

Auto transfer the plywood and sawing the horizontal sides firstly then sawing the vertical sides.

With firmly structure and sawing smoothly.

High efficiency and precision plywood sawing.one time cutting several boards together, total height 60mm one time.

The cutting size is adjustable from 3*6ft to 4*8ft range.

Auto feed boards by the suction disc loader and auto stacking.

Main components:

Infrared positioning,pre-loading boards device, longitudinal and transversal trolley fasten,moving and sawing system, auto hydraulic stacking parts.

Technical Parameters

| MODEL | ESM-4SAW |

|---|---|

| Control method | NC, automatic |

| Cutting board size | 1220*2440 mm (3*6' to 4*8' adjustable) |

| Cutting thickness | 3-60mm |

| Saw blade power | 9kw*4units |

| Auto board forwarding power | 2.3 kw*2 (servo motor) |

| Lifting power | 3 kw |

| Install size | 6500*5000*1200 mm |

| Weight | 5800kg |

| Capacity | 2000-3000 pcs/day |

| Auto feeder type | suction disc feeding |

Key Highlights for this 4x8 ft auto edge cutting machine:

Intelligent cutting, smooth and safe operation, precise and efficient.

The saw blade can automatically adjust its speed according to cutting boards conditions, preventing blade stalling.

The main body structure is strengthened, made of high-quality steel plate, with high stability and no deformation.

Major electrical components are from well-known brands such as "Omron" and "Schneider", ensuring safety and reliability.

Utilizing high-precision and wear-resistant guide rails along with strong infrared positioning, achieving high cutting accuracy with diagonal error ≤0.5mm.

Equipped with a pre-installed board device, requiring only two operators; with a yield of 3000 to 4000 sheets per shift at 16mm thickness, it's efficient and energy-saving. (auto board feeding machine adding also available )

Equipped with waste removal mechanism, automatically removing trimmings wastes from cutting edges and corners.

Specially designed powerful dust removal device, effectively cleaning dust from both top and bottom.

After Sale :

After Sale :

Pre-sale services:

1) Free consult to help you choose suitable veneer making or plywoodworking machine.

2) Base on your production improvement or equipment upgrading needs, make full set plywood,veneer production solutions. and offer the machine drawings.

3) Offer detail machine technical parameters and quotations, after confirm each other, sign the PO or invoice.

4) Invite customers to visit workshops and test plywood machine working.

Services during the sales:

1) Updating the machinery manufacturing process.

2) Strict inspection of machine quality during each manufacture and assemble process and detail tesing before delivery.

3) Free training the machine operating and using, make the user manual help customer comand the skills.

4) Confirm the custom clearance documents and prepare delivery.

After sale services:

1) 7/24 hours engineer ready to service to solve problems.

2) Full life spare parts and online machine debugging supporting.

3) Professional engineers installing and trainning service.

4) overseas service of machine upgrading and maintance.

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

woodmachine@hotmail.com

Address:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.