E-mail: info@plywoodworking.com Phone: +8615854986399

E-mail: info@plywoodworking.com Phone: +8615854986399

Specification

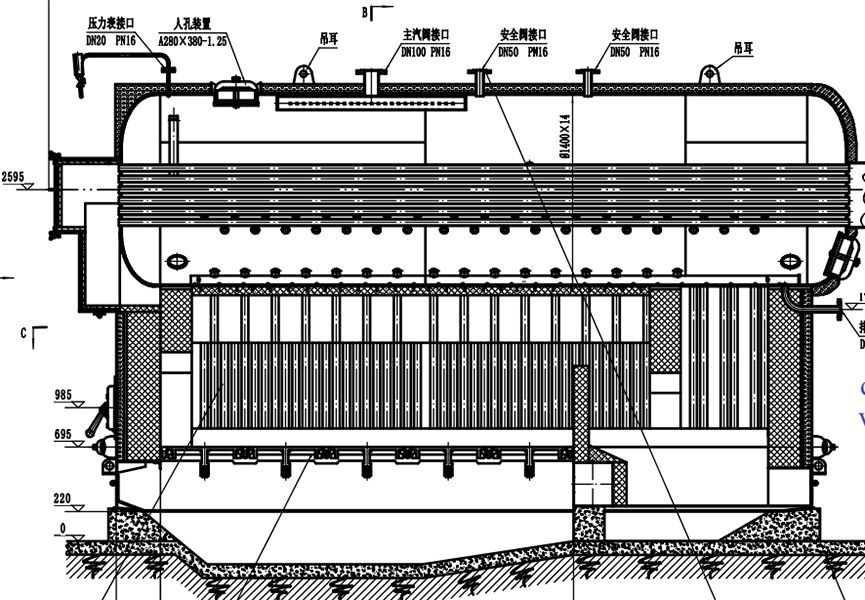

MODEL: 4-1.25-T

Rated steam capacity: 4T/h

Working pressure: 1.25 MPA

Normal steam temperature: 194℃

Stove heating area: about 52 ㎡

Design heating efficiency: 86.42 %

Full load fuel consume: 743 kg/h

Design fuel: wood,coal, biomass fuel

Water volume: 7.67 m³

Grate area: 5.43 m³

Grate type: fixed/movable

Burning medium can be biomass particle (biomass pellet), wood wastes like wood barks, wood veneers or wood,plywood,bamboo leftover material during production. High heating efficient and save fuel, safety production guarantee.Biomass Thermal Oil Boiler

This biomass steam boiler: A boiler designs to generates steam by burning biomass materials like wood chips, sawdust, or agricultural waste. Biomass steam boilers are utilized in industries such as wood working and paper, textile, food processing, and power generation. It can offer a renewable and sustainable alternative to traditional fossil fuel boilers, reducing greenhouse gas emissions and promoting environmental sustainability. With advancements in technology, biomass steam boilers are becoming increasingly efficient and cost-effective, contributing to a greener wood working production and future.

Low Operating Costs: The boiler utilizes wood biomass pellets, a newly supported and promoted environmentally friendly fuel by the government. It's a renewable resource with high calorific value, low cost, and wide availability, operating at only one-fourth the cost of electric boilers and less than half the cost of fuel (gas) boilers.

High Automation Level: Equipped with a digital integrated controller, the boiler can automatically control combustion conditions according to user settings. It's easy to operate with automatic ignition, feeding, and ash cleaning, comparable in convenience to fuel (gas) boilers.

Compliance with National Safety Standards: Manufactured and installed in high-standard production workshops, utilizing high-quality auxiliary machinery, accessories, and automatic control equipment, ensuring safe and stable boiler operation.

Sleek Appearance: The boiler boasts a novel design, presenting an elegant and stylish aesthetic.

This biomass steam boiler: A boiler designs to generates steam by burning biomass materials like wood chips, sawdust, or agricultural waste. Biomass steam boilers are utilized in industries such as wood working and paper, textile, food processing, and power generation. It can offer a renewable and sustainable alternative to traditional fossil fuel boilers, reducing greenhouse gas emissions and promoting environmental sustainability. With advancements in technology, biomass steam boilers are becoming increasingly efficient and cost-effective, contributing to a greener wood working production and future.

Low Operating Costs: The boiler utilizes wood biomass pellets, a newly supported and promoted environmentally friendly fuel by the government. It's a renewable resource with high calorific value, low cost, and wide availability, operating at only one-fourth the cost of electric boilers and less than half the cost of fuel (gas) boilers.

High Automation Level: Equipped with a digital integrated controller, the boiler can automatically control combustion conditions according to user settings. It's easy to operate with automatic ignition, feeding, and ash cleaning, comparable in convenience to fuel (gas) boilers.

Compliance with National Safety Standards: Manufactured and installed in high-standard production workshops, utilizing high-quality auxiliary machinery, accessories, and automatic control equipment, ensuring safe and stable boiler operation.

Sleek Appearance: The boiler boasts a novel design, presenting an elegant and stylish aesthetic.

Steam Boiler User Manual

1.Parts of the user manual and safety using regulars: for the coal or biomass fired steam boiler.

Technical Regulations, (simple version, for the more detail guide book, please contact supplier)

Boiler Installation Engineering Construction and Acceptance Standards" related regulations.

2. This drawing is only used as a reference for the user to design and install the pipeline. The user can also arrange it according to the actual situation, but it must comply with TSG 11-2020 "Boiler Safety Technology

3. Boiler walls, flue gas ducts, various thermal equipment, thermal pipes and valves should have good sealing and thermal insulation properties. The difference between the outer surface temperature of the furnace and the ambient temperature beyond 300mm from the door (hole) shall not exceed 25°C, the difference between the surface temperature of the furnace roof and the ambient temperature shall not exceed 50°C, and the surface temperature of various thermal equipment, thermal pipes, and valves shall not exceed the ambient temperature. The difference shall not exceed 25°C.

4. After the welding seam of the butt joint of the pipeline (pipe) is qualified by the visual inspection, the radio graphic inspection shall be carried out according to NB/T47013.2-2015 .Less than 10% of the joints shall be subjected to radio graphic inspection. Technical level no lower than AB level, the quality of welded joints shall not be lower than II level.

5. Properly arrange the support during installation, but it should meet the expansion requirements; the safety valve should be equipped with an exhaust pipe, which should lead directly to a safe place, and have a sufficient cross-sectional area to ensure smooth exhaust, and the exhaust pipe should be fixed. , there should not be any external force from the exhaust pipe applied to the safety valve, and valves are not allowed on the safety valve exhaust pipe; the bottom of the safety valve exhaust pipe should be equipped with a drain pipe connected to a safe place. Valves should not be installed; each boiler should be equipped with an independent sewage pipe, and the sewage pipe should minimize the number of elbows to ensure smooth sewage discharge and be connected to an outdoor safe place or sewage tank. Proper safety measures must be taken.

6. For boilers using biomass as fuel, ash accumulation at the slag outlet and high-temperature corrosion on the heating surface should be prevented; the feeding device between the fuel bin and the combustion chamber should be connected with the boiler fan.Lock.

7. After the installation of boilers, pipes, instruments, and valves, the water pressure test must be carried out as a whole after passing all quality inspections. The hydraulic test is in accordance with GB/T16508.4-2013

and the test pressure is 1.65MPa.

8. The preparation of boiler measurement, detection and control instruments should meet GB/T16508.5-2013 "Shell Boiler Part 5: Safety Accessories and Instruments", TSG 91-2021

9. 1.25-SC Ⅱ type boiler supporting sub-cylinder model: 325FQ100-1.25, only limited to installation in the boiler room

After Sale :

Pre-sale services:

1) Free consult to help you choose suitable veneer making or plywoodworking machine.

2) Base on your production improvement or equipment upgrading needs, make full set plywood,veneer production solutions. and offer the machine drawings.

3) Offer detail machine technical parameters and quotations, after confirm each other, sign the PO or invoice.

4) Invite customers to visit workshops and test plywood machine working.

Services during the sales:

1) Updating the machinery manufacturing process.

2) Strict inspection of machine quality during each manufacture and assemble process and detail tesing before delivery.

3) Free training the machine operating and using, make the user manual help customer comand the skills.

4) Confirm the custom clearance documents and prepare delivery.

After sale services:

1) 7/24 hours engineer ready to service to solve problems.

2) Full life spare parts and online machine debugging supporting.

3) Professional engineers installing and trainning service.

4) overseas service of machine upgrading and maintance.

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

woodmachine@hotmail.com

Address:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.