E-mail: info@plywoodworking.com Phone: +8615854986399

E-mail: info@plywoodworking.com Phone: +8615854986399

Specification

MODEL: ESM-260ZY-70

Log Diameter: 130-800 mm

Log Length.Max.: 2700 mm

Rub Roller Diameter: 278, 178 mm

Single Roller Power: 11 kw

Double Roller Power: 18.5 kw

Hydraulic System Power: 5.5 kw

Knife size: 2800*180*16mm

Log debarking speed: 50m/min

Weight: abt. 8000 kg

Wood waste chipping function: YES

Support roller function: YES

This heavy duty type log debarking machine with wood wastes chipper and support roller, suits very very big hard logs high efficiently debarking before peeling process.It can also make working in the automatic veneer peeling line.

High debarking efficiency.Strong structure for many years using.

Easy operation. With rolling support roller system in bottom for Heavy big logs. Very heavy duty structure. Much more upgrades than the 500mm debarker.

Hydraulic type, manual control. Even bend logs, heavy logs with branches can efficiently process.

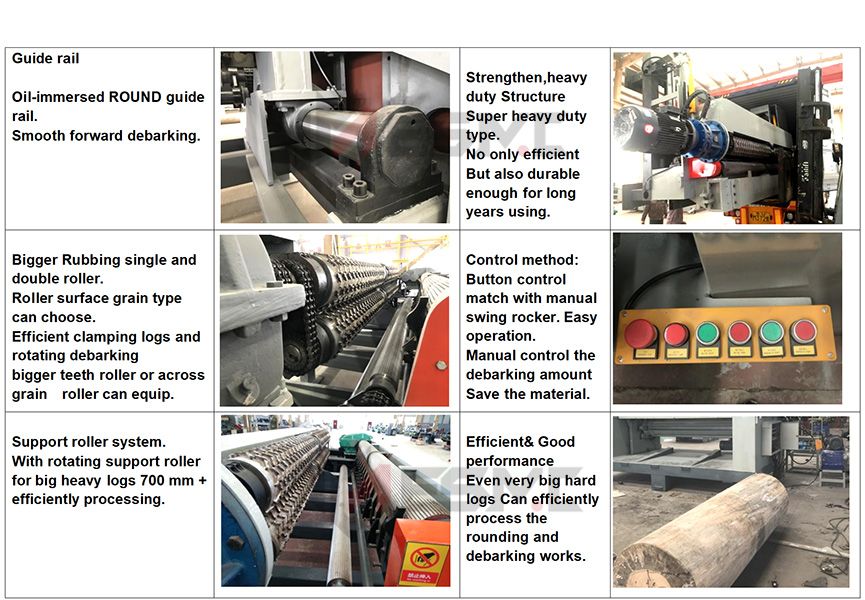

Oil-immersed ROUND guide rail.

Smooth forward debarking. Strengthen,heavy duty Structure.Super heavy duty type.

No only efficient But also durable enough for long years using.

Bigger Rubbing single and double roller.

Roller surface grain type can choose.Efficient clamping logs and rotating debarking

bigger teeth roller or across grain roller can equip.

Control method:

Button control match with manual swing rocker. Easy operation.

Manual control the debarking amount,Save the material.

Support roller system.

With rotating support roller for big heavy logs 700 mm + efficiently processing.

Efficient& Good performance.Even very big hard logs can efficiently process the rounding and debarking works.

Please feel free to contact for the heavy duty log debarking machine from 4ft to 10 ft with different models. We will try best make the good and stable veneer plywoodworking machine to you. And offer the full term after sale service. ESMC appreciate your support and trust.

After Sale :

Pre-sale services:

1) Free consult to help you choose suitable veneer making or plywoodworking machine.

2) Base on your production improvement or equipment upgrading needs, make full set plywood,veneer production solutions. and offer the machine drawings.

3) Offer detail machine technical parameters and quotations, after confirm each other, sign the PO or invoice.

4) Invite customers to visit workshops and test plywood machine working.

Services during the sales:

1) Updating the machinery manufacturing process.

2) Strict inspection of machine quality during each manufacture and assemble process and detail tesing before delivery.

3) Free training the machine operating and using, make the user manual help customer comand the skills.

4) Confirm the custom clearance documents and prepare delivery.

After sale services:

1) 7/24 hours engineer ready to service to solve problems.

2) Full life spare parts and online machine debugging supporting.

3) Professional engineers installing and trainning service.

4) overseas service of machine upgrading and maintance.

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

woodmachine@hotmail.com

Address:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.