E-mail: info@plywoodworking.com Phone: +8615854986399

E-mail: info@plywoodworking.com Phone: +8615854986399

Specification

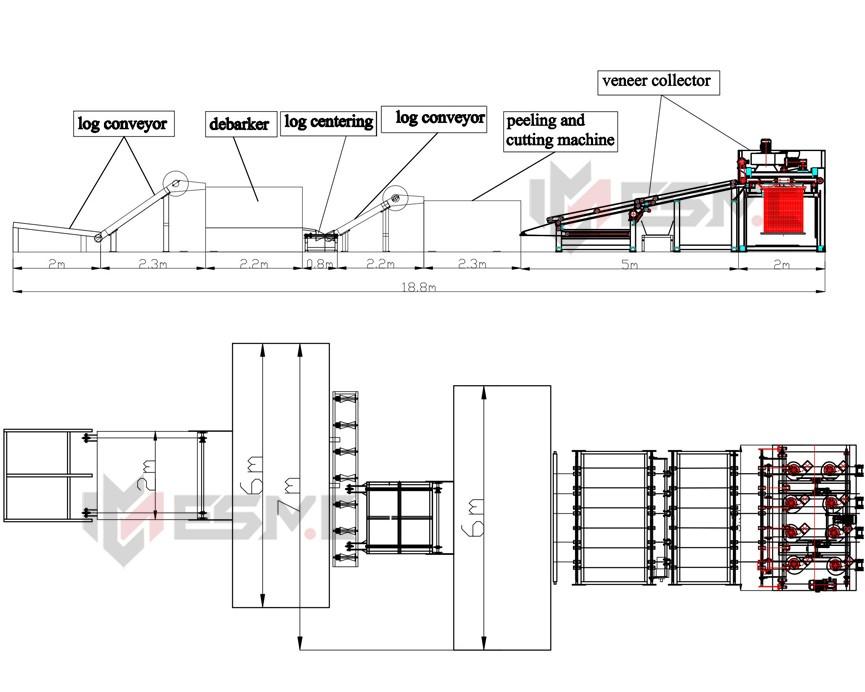

Model: ESM-L8FT

Peeling speed: 30-100 m/min

Veneer thickness: 0.5-4 mm

Processing log diameter: 40-500 mm

Log length: 1700-2650 mm

Log loading machine: 2 unit

Log conveyor machine: 1 unit

Log debarking and rounding machine: 1 unit,8ft

Heavy Duty Peeler: 1 unit, 8ft

Auto veneer stacker: 1 unit, 8ft

Peeling line space need: abt 20x10m

This semi auto veneer spindle less lathe suitable wood log diameter no bigger than 600-700 mm. And the most used core veneer thickness peeled is 0.5-3mm. The output for rotary cutting lathe is is big. Common peeling size is 4ft, 6ft,8ft and 10 ft auto or semi auto peeling line can choose and customize. Peeling speed is 30-80m/min can adjust.

This spindle less wood peeling machine line , main parts and components:

1. Simple type load loading machine for veneer peeler.

2. Spindle less wood log debarker for below 600-700mm logs.

3. Log transfer machine and the loading machine for debarking machine.

4. 8ft heavy duty spindle less peeling lathe (non chuck peeler)

5. Automatic veneer stacking machine for collect veneers orderly.

Automatic or semi auto feeders can save labour and improve efficiency.

Strengthen structure for peeling machine and debarking machine. Equip bigger motors and stronger rollers. Can well process both hard and soft longs into brilliant veneers. Double motor for both single roller and double roller in the peeler. Peeling and cutting directly to get your need veneer size.

The knife carriage forwarding and cutting veneer use servo motors to keep the smooth and stable veneer peeling works.also can develop the veneer veneer thickness accuracy, save the power costs.

Inverter adjust the peeling speed , matched with the hard teeth gear box.Peeling speed 30-100m /min can adjust. Suiting different kinds logs peeling pressure. And the noise is small.

This line need about 20x10m space to working and operating.

The auto stacking machine can save at least 2-3 labour with a high speed collecting veneers. Save costs, improve output.Besides, veneer quality is protected well.

For the veneer peeling line need 2-3 workers the complete production. And the full automatic upgrading line can make it only need 1 worker. Feel free to contact us for a suitable peeling production plan!

1,Processing of smooth, uniform wood veneer board surface.

2, High working efficiency and simple control and simple maintance.

3,Take with higher standard lead screws, rollers and spare parts keep longer service life.

4, High quality veneers, save your costs and improve production output.

5,High accurate and stable veneers thickness. common core veneers, the thickness among 1.4-1.6mm if you set veneer as 1.5mm.

After Sale :

Pre-sale services:

1) Free consult to help you choose suitable veneer making or plywoodworking machine.

2) Base on your production improvement or equipment upgrading needs, make full set plywood,veneer production solutions. and offer the machine drawings.

3) Offer detail machine technical parameters and quotations, after confirm each other, sign the PO or invoice.

4) Invite customers to visit workshops and test plywood machine working.

Services during the sales:

1) Updating the machinery manufacturing process.

2) Strict inspection of machine quality during each manufacture and assemble process and detail tesing before delivery.

3) Free training the machine operating and using, make the user manual help customer comand the skills.

4) Confirm the custom clearance documents and prepare delivery.

After sale services:

1) 7/24 hours engineer ready to service to solve problems.

2) Full life spare parts and online machine debugging supporting.

3) Professional engineers installing and trainning service.

4) overseas service of machine upgrading and maintance.

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

woodmachine@hotmail.com

Address:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.