E-mail: info@plywoodworking.com Phone: +8615854986399

E-mail: info@plywoodworking.com Phone: +8615854986399

Industry News: Advances in Plywood Edge Cutting Machines

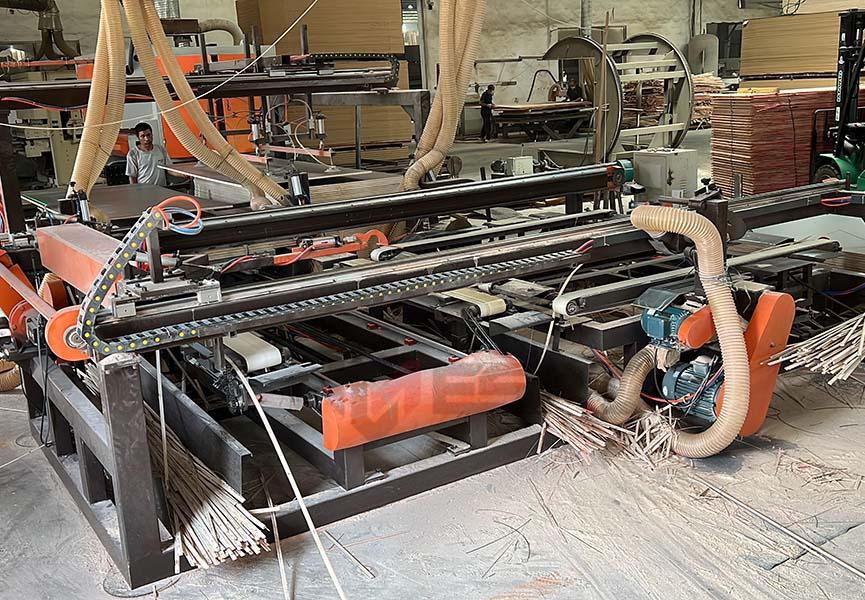

The plywood industry, particularly in wood based panel board production centers in Shandong province, Linyi City , has seen significant advancements in edge cutting technology with the introduction of automatic 4-sides plywood edge trimming machines. These machines, widely used in various plywood making production, have transformed how plywood is processed, offering manufacturers enhanced speed, precision, and efficiency. One of the standout models is the **Auto 4-Sides Plywood Edge Trimming Saw**, designed for high-capacity production and precise edge cutting.

In regions like Linyi , known for their expertise in plywood making machinery , these innovations have become critical to maintaining a competitive smooth plywood edge quality without edge breakage. The latest machines can process multiple boards simultaneously, achieving production speeds of up to 3000-4000 sheets per day. With advanced features like saw blade speed adjustments, infrared positioning, and high-precision guide rails, manufacturers can now achieve cutting accuracies with diagonal errors as low as 0.5mm.

Automated systems for board feeding, in built stacking to save space, and waste removal shelfs further enhance production efficiency, reducing the needs for more manual labor. In response to growing environmental concerns and save your costs, many of these machines are equipped with powerful dust removal systems, ensuring a cleaner and safer workspace.

In order to improve the plywood production quality and efficiency and continue to lead in plywood manufacturing, intelligent automation in edge cutting technology is becoming a key driver for growth and innovation in the industry.

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

woodmachine@hotmail.com

Address:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.